Heat pump projects are growing rapidly throughout Alaska, with incentives in the form of tax credits and upcoming rebates through Alaska Housing Finance Corporation (AHFC) and grant programs set to help install over 7,000 heat pumps throughout coastal communities and the Northwest Arctic Borough. On Tuesday, Sep. 24, 2024, the Alaska Energy Training Group convened more than 40 energy professionals to share and discuss heat pump considerations, best practices, and technology for cold climates.

The Alaska Energy Training Group is a quarterly meetup of energy professionals facilitated by REAP’s Alaska Network for Energy Education and Employment (ANEEE) and in partnership with the Denali Commission. The group’s mission is to improve coordination and collaboration in training, troubleshooting, workforce development, and technical assistance programs and investments throughout Alaska.

The group encompasses a broad swath of regions and industries in Alaska. Prior meetings have discussed collaborative topics, such as monitoring and maintenance tools for water and energy infrastructure and training practices for both larger natural development companies and smaller diesel mechanic shops. At its fourth meetup, Jenny Starrs, Program Manager for REAP’s ANEEE initiative, facilitated a discussion on air source heat pumps where two experts, Phil Kaluza and Dr. Diana Fisler, presented on heat pump considerations, best practices, and technology for cold climates. The discussion ended with opportunities for participants to ask questions and share updates and resources.

The current economic incentives, last year’s particularly snowy winter, and another winter on the horizon made for a timely opportunity for experts to share knowledge focused on heat pumps in cold climates. With a wealth of experience in heat pump installation and maintenance in cold climates, former AHFC state energy program manager Phil Kaluza kicked off the presentations by sharing his lessons learned from working on heat pumps in Seward last winter. While Phil explained that heat pumps require little maintenance compared to other heating systems—as long as the indoor screens and coils on the outside of units are cleaned—he also shared some of the unique challenges and solutions he’s worked through. To avoid snow and ice-induced complications, Phil recommended protecting outdoor units from snow drifts and running water, and installing them off the ground. He also shared that overhangs and covers can protect outdoor units from snow and ice while maintaining efficiency, as long as they also allow for circulation and access to the unit’s coils and circuit boards.

Discussions like these can not only help other heat pump installers, technicians, and owners prevent and troubleshoot related challenges, but they can also provide insight, inspiration, and improvements for technological research and development.

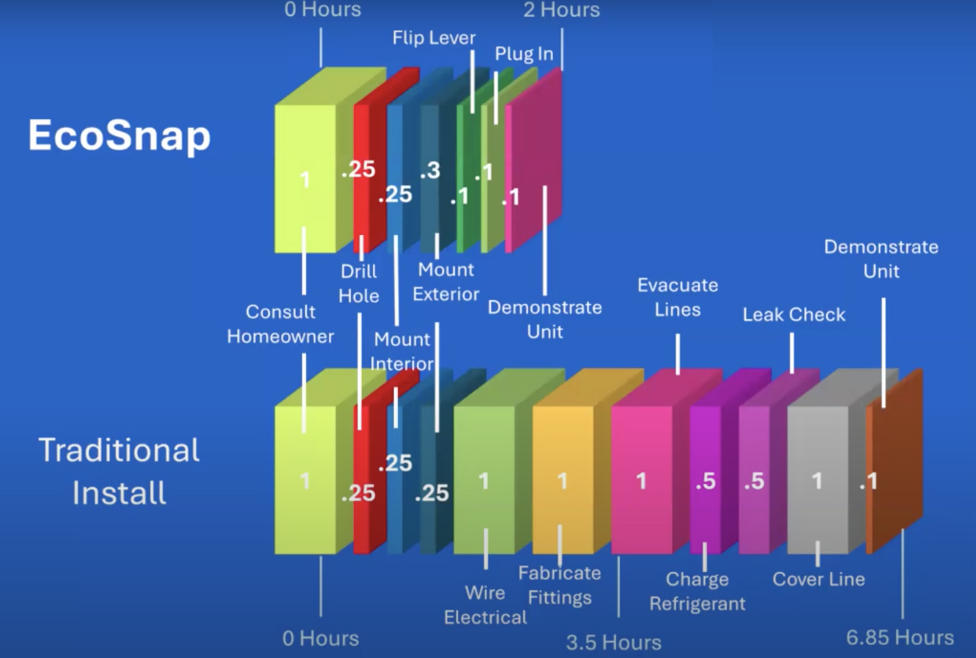

Dr. Diana Fisler, a materials building scientist who presented after Phil, founded EcoSnap to address a key challenge both she and Phil identified with heat pump installation: it can be difficult to find people willing to install heat pumps. Heat pump installation often requires the expertise of multiple different trades, which leads to increased costs and time to install.

EcoSnap offers patented, easy installation technology for mini split heat pumps. In her presentation, Dr. Fisler described how EcoSnap can shorten installation time and then went into the multiple grant-funded projects that her company is working on. The first project is working to develop an interoperable Toyo stove and mini heat pump system that integrates with the homeowner’s thermostat to automate the switch between the stove and heat pump based on energy use and efficiency. Another project is working to develop a modular unit to improve the heat pump’s serviceability and accessibility, especially in rural areas. Finally, Dr. Fisler shared that EcoSnap is researching reliability and cold climate performance in Alaska’s unique climate.

Following the presentations, participants had the opportunity to ask questions and discuss solutions. Topics ranged from the lifecycle of heat pumps—usually up to 20 years—to how to get people interested in becoming heat pump installers. While companies like EcoSnap have tried to make heat pump technology more cost and time-efficient to install, the discussion underscored the need for more trained installers and HVAC technicians in the state, and also shared training initiatives from Alaska Vocational Technical Center in Seward and others.

In the final minutes, participants shared their own updates and resources regarding heat pumps, including information regarding a heat-pump only installation company based in Juneau, continued heat pump installer training through University of Alaska Southeast, and a heat pump lab launching this fall through University of Alaska Anchorage and LG Electronics.

Cold climate heat pumps are among many exciting clean energy projects gaining momentum in Alaska. By providing a platform for energy experts to meet and share their experiences and resources, the Alaska Energy Training Group helps identify the challenges and successes of developing and maintaining clean energy projects in the state. Networks like the Alaska Energy Training Group are important to ensure that people have positive experiences with clean energy projects and to, ultimately, accelerate the work towards Alaska’s transition to a clean energy economy.

Watch the whole conversation here, learn more and sign up to join the Alaska Energy Training Group on their webpage, and catch the group’s next meeting on Dec. 3 at 11 a.m.

Want to learn more about heat pumps and energy efficiency at home? Check out AHFC’s “Heat Pumps in Alaska” booklet and the Home Energy Efficiency adult education modules offered through REAP and AHFC that are featured in a previous blog post.